DEEPBIT has more than 17 years of experience in independent bit design.

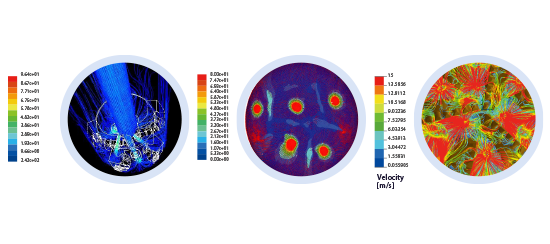

Deep Bits applies CFD software to mathematically simulate the PDC bit’s flow field in 3D. This effectively reduces the need for long-term, inconvenient and high costing structural adjustments for optimised hydraulic design.

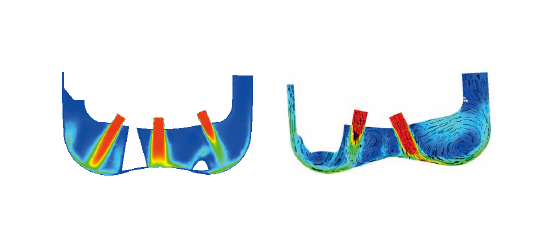

Mathematical simulation takes into consideration the impact of nozzle location, diameter, quantity and cutters and the relationship between the downward jet flow, upward jet flow and jet reverse flow in the 3D model. This effectively resolves the problems of retention, back-flow and whirlpool in the bottom hole flow field.

The hydraulic structure is optimized through mathematical simulation that helps keep the bit cutters cool and the bit surface lubricated, and effectively reducing the balling tendency.