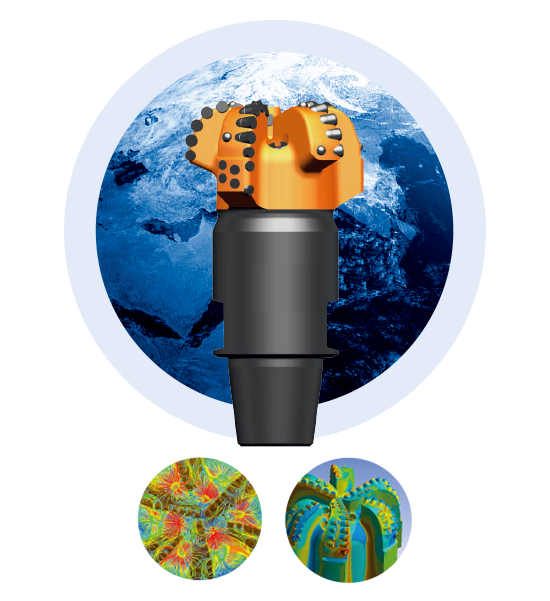

Cutter Technology

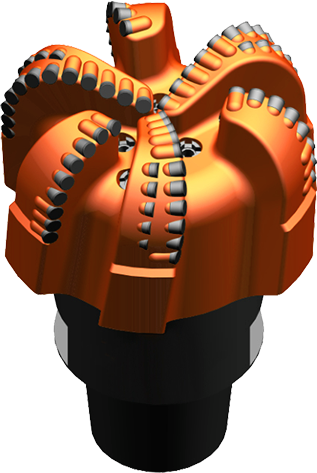

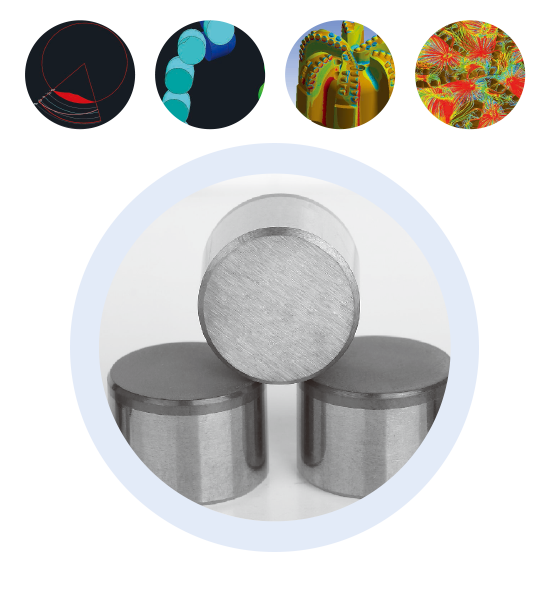

orBIT Premium PDC Cutters

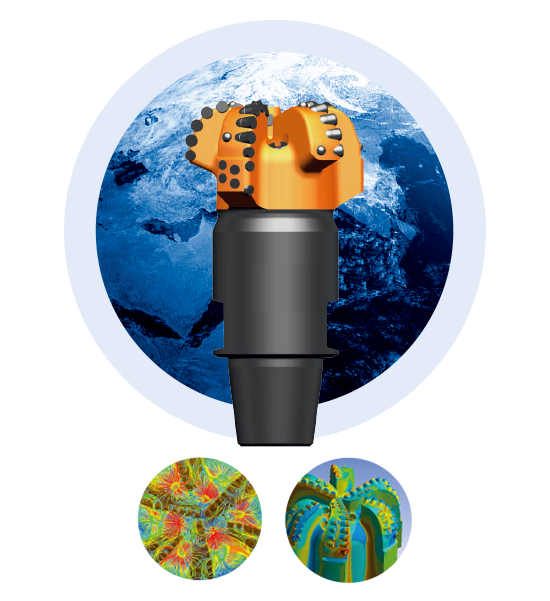

Deep Diamond Premium cutter technology is an innovative and patented approach to providing customer with industry leading, thermally stable, high performance cutters. A unique double leaching process ensures that the cutters integrity, even in the most challenging applications, outperforms regular leached and other PDC cutters. The development of this complex manufacturing technology enables Deep Diamond products to achieve superior performance in fields around the world.

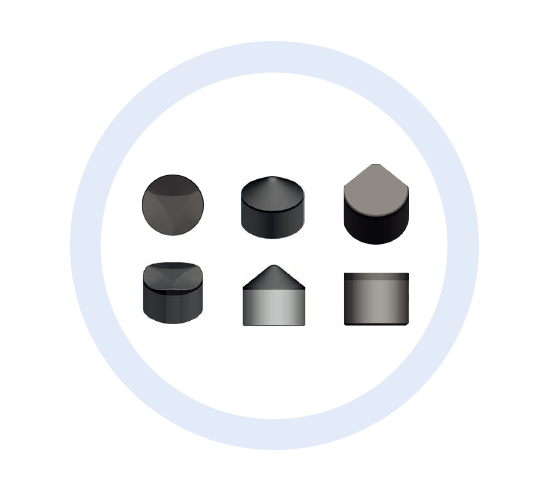

Geometric Shapes for a Longer Bit Life

With our commitment to customized designs, DEEPBIT orBIT Series employs distinct geometric-shaped cutters according to the needs of each specific application challenge.

The right choice for the job

These optional features are available with the orBIT Series and implemented as determined best for the application.

- Active short gauge

- Passive long gauge

- Spiral Type

Patent No.: ZL201420435200.5

- Reduces the volume of the cavity formed by the end of the gauge and the borehole wall

- Improves movement with the junk slot’s funnel-shaped structural design

- Provides the end of the gauge with the ability to break rock

The patented fishtail shape is used at the end of gauge

Tapered cutter on gauge

Design Features:

- Tapered cutters are arranged in the back row as support cutters

- Tapered cutters have a higher exposure than the main cutters (front-row cutters)

Back row tapered cutters increase the drilling efficiency and improve the bit life in hard and abrasive applications where long bit life and higher ROP can be achieved.

Front-row cutter track

Back-row tapered cutter

Patent No.: ZL2017206008595

Design Features:

- Conventional blade structure and non-gauge blade structure

- Increased junk slot space for smoother hydraulic flushing and improved anti-balling effectiveness.

Nomenclature

Four numbers are used in the bit type name

The first and second number together stand for the cutter sizes, for example:

- 11 stands for 11mm diameter cutter

- 13 stands for 13mm diameter cutter

- 16 stands for 16mm diameter cutter

- 19 stands for 19mm diameter cutter

The third number stands for blade count, for example:

- 4 stands for 4 blades

- 5 stands for 5 blades

- 6 stands for 6 blades

- 7 stands for 7 blades

- 8 stands for 8 blades

The fourth number stands for bit profile:

- 1 stands for extreme short profile

- 2 stands for short profile

- 3 stands for medium profile

- 4 stands for long profile

- 5 stands for extreme long profile

8-1/2''

Bit Diameter

3.5” ~ 26”

o

r

Prefix

OR = orBIT series

M

M Matrix Body

S = Steel Body

1

3

Cutter Size

08 = 8 mm cutters

11 = 11 mm cutters

13 = 13 mm cutters

13 = 13 mm cutters